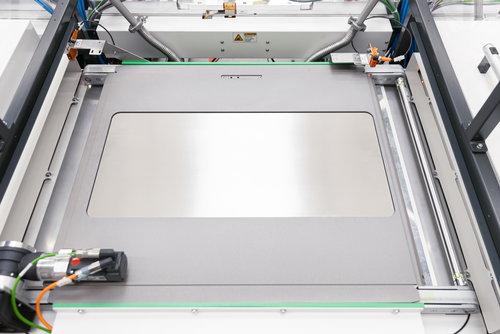

The HISS600 is the first system for 24/7 production in this market using physical vapor deposition (PVD). It utilizes magnetron sputtering for precious metal coatings from rotary targets with a high target utilization. These coatings reduce the interfacial contact and through-plane resistance (ICR/TPR) and provide corrosion protection at electrolysis anode potential. The machine will be operational by mid-2024.

Why PVD?

Compared to established technologies like electroplating, PVD enables thinner layers, resulting in more cost-efficient coating due to lower consumption of precious metals.

Why VON ARDENNE?

Our customer chose to work with us thanks to our ability to meet their ambitious timeline and demand for high flexibility. They also valued our technological expertise and experience in the hydrogen industry. Beyond that, the proven track record of the HISS600 across various industries played a pivotal role.

What makes the tool special?

The HISS600 enables you to coat bipolar plates and porous transport layers with an annual capacity in the gigawatt range of accumulated stack power. And it is compatible to industry 4.0 standards of smart manufacturing. Thanks to its modular design, it's extremely flexible and can be configured to the specific requirements of our customers.

For more information about our offerings for the hydrogen power market, click here.